At Leafield Marine we are dedicated to safety. Many of our products are used by customers in lifesaving applications or high-risk scenarios. Therefore, it is key that they are consistent in their performance. We make sure all our products are made to the highest quality. Whether it is a simple RIB Inflation valve, or a life raft rapid inflation system.

Design

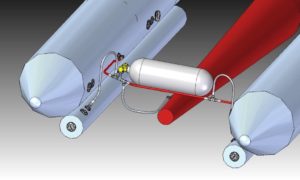

Leafield Marine know the importance of safety. That is why we focus on it from the start of the process. All of our products are designed carefully for use in all conditions. We are an ISO 9001:2015 approved company. We have further had many of our products approved to SOLAS (ISO:15738), PE(S)R and PED standards. Our designers are also happy to work alongside your company to create the best product for your needs. This processes is key in the design of life rafts and sea safety equipment as these devices are very complex and specific. Therefore, we want to make sure we create the most effective system we can.

Materials

Leafield Marine products are made with Acetal (POM) plastics. This material is commonly used to make precision parts that require high stiffness and dimensional stability. Acetal plastic is known for its strength and rigidity. This makes it ideal for valve production. It maintains its functionality up to

+65 °C and down to −40 °C. Therefore, our products stay stable in all conditions. We use this material to give our products an increased service life.

Testing

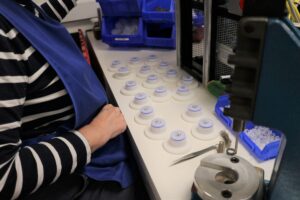

We test our products intensely before we ship them. For example, All Inflation/ Deflation and Pressure Relief Valves are pressure tested one at a time in production to make sure they are up to our high standards. Our engineers rigorously expose the valves to salt spray, UV, Sand, and Aluminium Oxide for wear & function tests to ensure they can withstand many different working environments.

Fitting & Further

Leafield Marine’s valves clamp easily into the fabric of a structure without compromising the construction. We provide simple fitting instructions for our clients and offer help and advice after purchase. Furthermore, we supply tools alongside our products. These make sure valves can be fitted and adjusted safely, without causing damage to the seal or structure.

We study safety and quality at all stages of the production process because we know our products play a key role in saving lives.

To find out more about our safety processes, get in touch today!